What we do.

Dash is an advanced engineering company with one-stop capabilities to provide a rapid response for high-end vehicle projects. We combine engineering design and development processes with the latest composites, robotics and additive manufacturing technology.

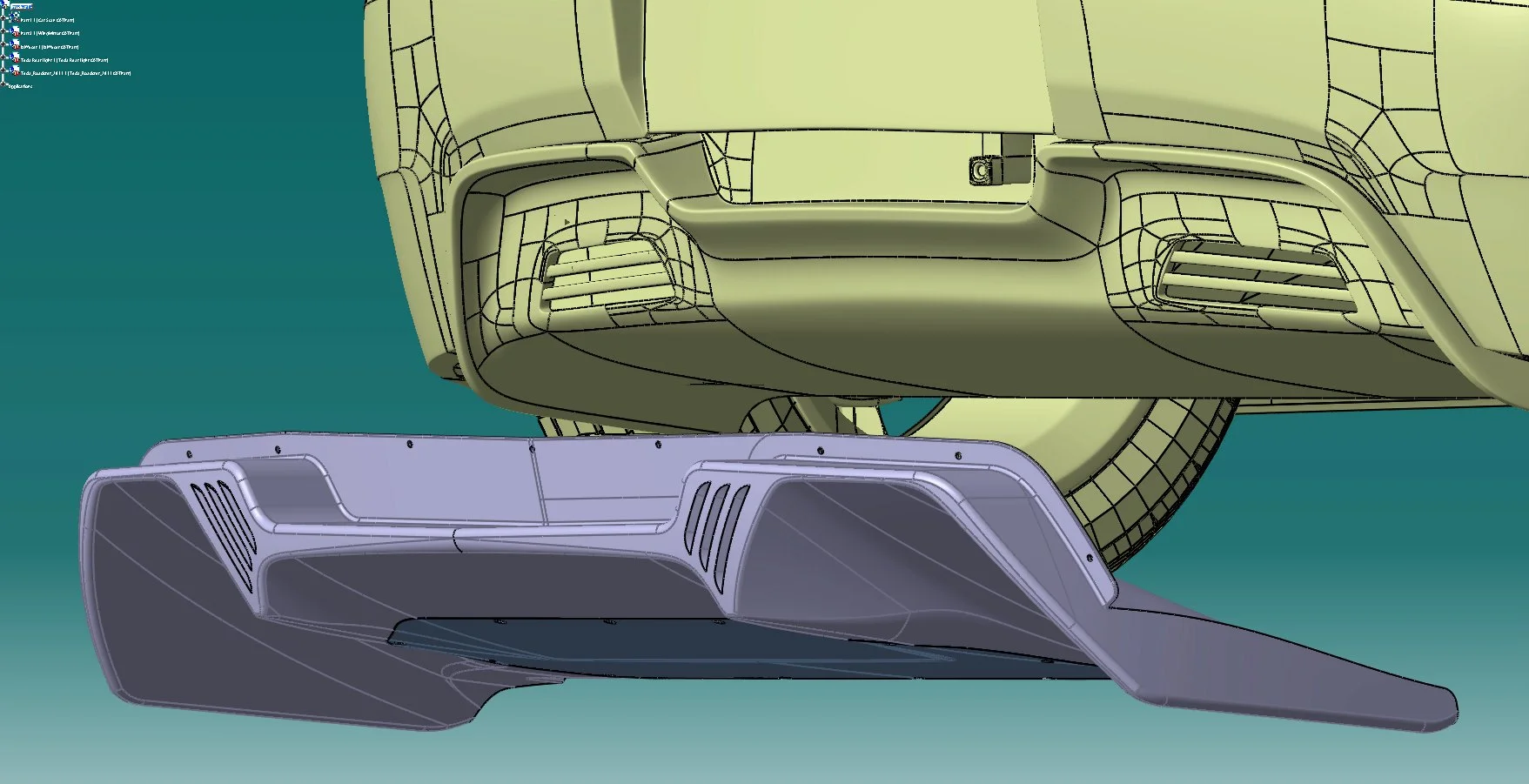

Design & Engineering

CAD (CATIA V5, Siemens NX)

CAE/FEA (Elfini, Ansys, Nastran, LS Dyna, PAM-CRASH)

CFD (TotalSIM)

HVAC simulations

Structural, impact, crush & rollover testing

Alongside design, engineering and homologation, we also offer a variety of management services for programmes, including production planning, product lifecycle management (PLM), Bill of Materials (BoM) management, and more.

Advanced Composites Laminating

As pioneers of the use of robotics in composites we have, over the past decade, significantly expanded our composite capabilities and capacity, including a new 20,000 sq ft production and testing site.

Three autoclaves (⌀1.6x4.5m)

Two precise Kuka 6-axis cutting robots

Large-scale polymer AM machines

Trim shop with diamond tooling

Off-site paint shop

Additive Composite Manufacturing: Prototypes, Tooling & More

Additive composite manufacturing (AM or 3D printing) enables us to produce parts and tooling within extremely short timescales – much faster than traditional methods – and to a high standard.

Stratasys F900 PRO (914 x 610 x 914mm)

Stratasys F250mc

Stratasys F400

Materials: ABS, PC-ABS, Nylon, CF Nylon, Antero, Ultem Aerospace Grades, Polycarbonate, Carbon-reinforced nylon (Nylon 12CF), and more

Direct tools & jigs with 0.25mm accuracy over 400mm

Up to 60% reduction in delivery time (just one week)

Up to 75% reduction in design time (just two days)

Fine build down to 0.12mm layers

Our expertise in additive manufacturing enables us to significantly improve the environmental impact of tooling, offering a true circular solution.